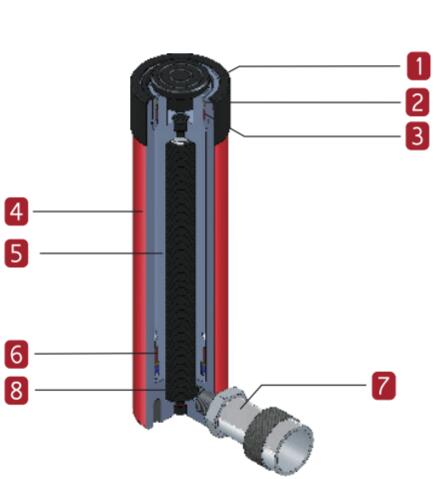

The BMS-SERIES is a general purpose spring return cylinder designed for use in production, Maintenance and fabrication applications. All BMS-Series cylinders feature a hard chrome cylinder bore and piston rod for maximum corrosion resistance. When combined with the bronze overlay on the piston bearing area and low friction surface treatment on the gland nut, this cylinder is suitable for the demanding applications. Cylinder body mounting threads and base mounting holes are included on most models. Optional tilt saddles are available for all models.

| For Use With Cylinder Capacity | Tilt Saddle Model | For Use With Cylinder Capacity | Tilt Saddle Model |

|---|---|---|---|

| ton | ton | ||

| 5 | - | 30 | ST-50 |

| 10 | ST-10 | 50 | ST-100 |

| 15 | ST-10 | 75 | ST-100 |

| 25 | ST-50 | 100 | ST-100 |

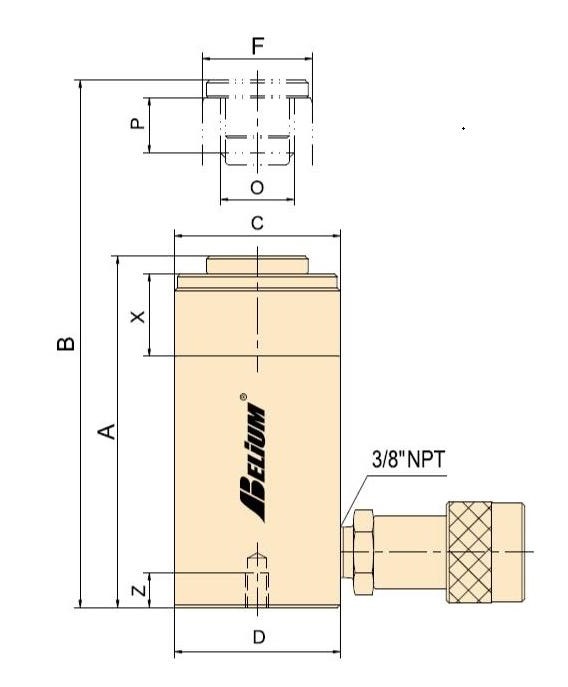

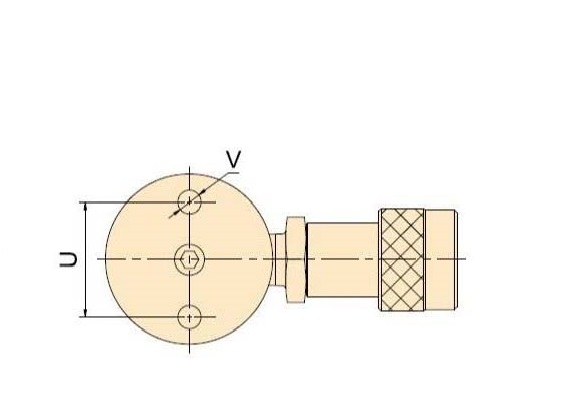

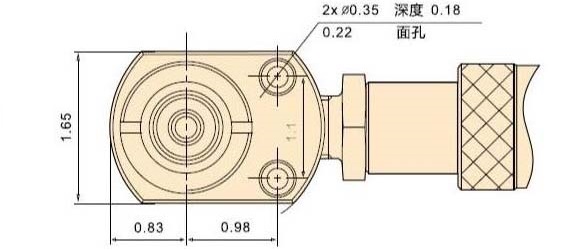

| Model | Cylinder Capacity | Stroke | Cylinder Effective Area |

Oil Capacity | Collapsed Height |

Extended Height |

Collar Thread |

CollarThread Length |

Outside Diameter |

Piston Diameter |

Piston Internal Thread |

Piston Thread Length |

Weight |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | C | X | D | F | O | P | ||||||

| Metric Ton | mm | CM² | CM³ | mm | mm | mm | mm | mm | mm | - | mm | kg | |

| BMS-50 | 5 | 16 | 7.1 | 11.4 | 42 | 58 | - | - | 59*42 | 25 | - | - | 0.8 |

| BMS-51 | 25 | 7.1 | 17.8 | 110 | 135 | 1.1/2"-16 UN | 28 | 38 | 25 | 3/4"-16 UNF | 16 | 1.0 | |

| BMS-53 | 75 | 7.1 | 53.3 | 165 | 240 | 1.1/2"-16 UN | 28 | 38 | 25 | 3/4"-16 UNF | 16 | 1.3 | |

| BMS-55 | 127 | 7.1 | 90.2 | 215 | 342 | 1.1/2"-16 UN | 28 | 38 | 25 | 3/4"-16 UNF | 16 | 1.7 | |

| BMS-57 | 177 | 7.1 | 125.7 | 273 | 450 | 1.1/2"-16 UN | 28 | 38 | 25 | 3/4"-16 UNF | 16 | 2.1 | |

| BMS-59 | 232 | 7.1 | 164.7 | 323 | 555 | 1.1/2"-16 UN | 28 | 38 | 25 | 3/4"-16 UNF | 16 | 2.3 | |

| BMS-101 | 10 | 26 | 14.5 | 37.7 | 89 | 115 | 2.1/4"-14 UN | 26 | 57 | 38 | - | - | 1.7 |

| BMS-102 | 54 | 14.5 | 78.3 | 121 | 175 | 2.1/4"-14 UN | 26 | 57 | 38 | 1"-8 UNC | 19 | 2.2 | |

| BMS-104 | 105 | 14.5 | 152.25 | 171 | 276 | 2.1/4"-14 UN | 26 | 57 | 38 | 1"-8 UNC | 19 | 2.9 | |

| BMS-106 | 156 | 14.5 | 226.2 | 247 | 403 | 2.1/4"-14 UN | 26 | 57 | 38 | 1"-8 UNC | 19 | 4.1 | |

| BMS-108 | 203 | 14.5 | 294.35 | 298 | 501 | 2.1/4"-14 UN | 26 | 57 | 38 | 1"-8 UNC | 19 | 4.9 | |

| BMS-1010 | 257 | 14.5 | 372.65 | 349 | 606 | 2.1/4"-14 UN | 26 | 57 | 38 | 1"-8 UNC | 19 | 5.6 | |

| BMS-1012 | 304 | 14.5 | 440.8 | 400 | 704 | 2.1/4"-14 UN | 26 | 57 | 38 | 1"-8 UNC | 19 | 6.4 | |

| BMS-1014 | 356 | 14.5 | 516.2 | 450 | 806 | 2.1/4"-14 UN | 26 | 57 | 38 | 1"-8 UNC | 19 | 7.2 | |

| BMS-151 | 15 | 25 | 21.2 | 53 | 124 | 149 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 3.2 |

| BMS-152 | 51 | 21.2 | 108.12 | 149 | 200 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 3.7 | |

| BMS-154 | 101 | 21.2 | 214.12 | 200 | 301 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 5.0 | |

| BMS-156 | 152 | 21.2 | 322.24 | 271 | 423 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 6.5 | |

| BMS-158 | 203 | 21.2 | 430.36 | 322 | 525 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 7.7 | |

| BMS-1510 | 254 | 21.2 | 538.48 | 373 | 627 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 8.7 | |

| BMS-1512 | 305 | 21.2 | 646.6 | 423 | 728 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 9.8 | |

| BMS-1514 | 356 | 21.2 | 754.72 | 474 | 830 | 2.3/4"-16 UN | 35 | 69 | 42 | 1"-8 UNC | 25 | 10.8 | |

| BMS-251 | 25 | 26 | 33.2 | 86.32 | 139 | 165 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 5.3 |

| BMS-252 | 50 | 33.2 | 166 | 165 | 215 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 6.2 | |

| BMS-254 | 102 | 33.2 | 338.64 | 215 | 317 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 8.0 | |

| BMS-256 | 158 | 33.2 | 524.56 | 273 | 431 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 10.3 | |

| BMS-258 | 210 | 33.2 | 697.2 | 323 | 533 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 12.1 | |

| BMS-2510 | 261 | 33.2 | 866.52 | 374 | 635 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 14.1 | |

| BMS-2512 | 311 | 33.2 | 1032.52 | 425 | 736 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 15.5 | |

| BMS-2514 | 362 | 33.2 | 1201.84 | 476 | 838 | 3.5/16"-12 UN | 54 | 86 | 57 | 1.1/2"-16 UN | 26 | 17.4 | |

| BMS-308 | 30 | 209 | 44.2 | 923.78 | 387 | 596 | 3.5/16"-12 UN | 50 | 102 | 57 | 1.1/2"-16 UN | 26 | 21.5 |

| BMS-502 | 50 | 51 | 70.9 | 361.59 | 176 | 227 | 5"-12 UN | 55 | 127 | 80 | - | - | 14.4 |

| BMS-504 | 102 | 70.9 | 723.18 | 227 | 329 | 5"-12 UN | 55 | 127 | 80 | - | - | 18.1 | |

| BMS-506 | 159 | 70.9 | 1127.31 | 282 | 441 | 5"-12 UN | 55 | 127 | 80 | - | - | 22.2 | |

| BMS-5013 | 337 | 70.9 | 2389.33 | 460 | 797 | 5"-12 UN | 55 | 127 | 80 | - | - | 34.3 | |

| BMS-756 | 75 | 156 | 103.9 | 1620.84 | 285 | 441 | 5.3/4"-12 UN | 45 | 146 | 95 | - | - | 30.5 |

| BMS-7513 | 333 | 103.9 | 3459.87 | 492 | 825 | 5.3/4"-12 UN | 45 | 146 | 95 | - | - | 50.3 | |

| BMS-1006 | 100 | 168 | 133 | 2234.4 | 357 | 525 | 6.7/8"-12 UN | 44 | 178 | 105 | - | - | 59.7 |

| BMS-10010 | 260 | 133 | 3458 | 449 | 709 | 6.7/8"-12 UN | 44 | 178 | 105 | - | - | 72.9 |