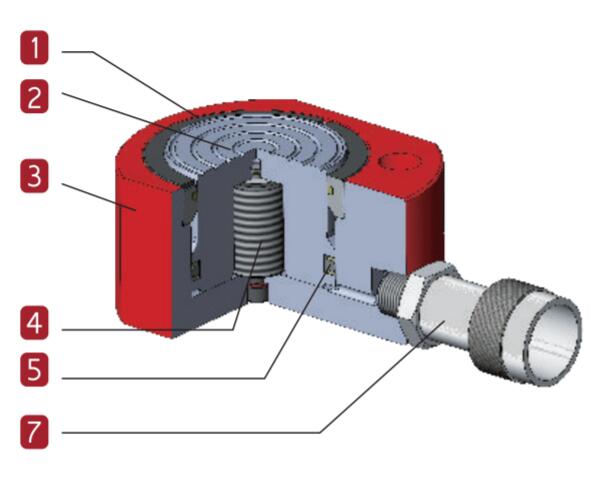

The bmsl-series is a spring return, compact flat cylinder designed for use in narrow spaces and areas with low overhead clearance. They can be used in maintenance, machinery leveling, and construction and mining applications. All BMSL-Series cylinders feature a hard chrome cylinder bore and piston rod for maximum corrosion resistance and bronze overlay piston bearing area to resist side load included damage. Mounting holes are standard on all models and a grooved piston rod end improves load grip.

The BMSL-series is a single acting spring return low profile cylinder. Its compact design combines maximum stroke with low collapsed height.

These cylinders are commonly used in construction, mining, rail and many other industries. They are ideal for jacking, weighing, testing, leveling and general maintenance applications. All BMSL-Series cylinders feature a hard chrome cylinder bore and piston rod for maximum corrosion resistance and bronze overlay piston bearing area to reduce scoring and increase service life. Optional tilt saddles are available for all models.

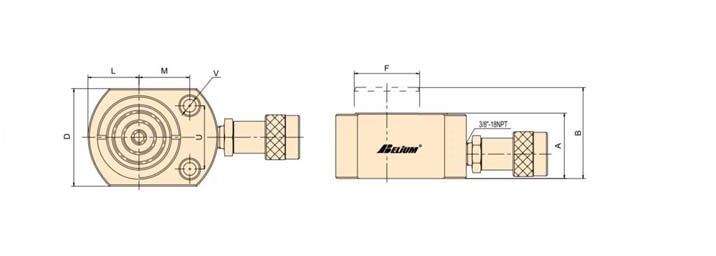

| Model | Cylinder Capacity | Stroke | Cylinder Effective Area |

Oil Capacity | Collapsed Height |

Extended Height |

Outside Diameter |

Piston Diameter |

Top Dimensions | Weight | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | B | D | F | M | L | V | U | ||||||

| Metric Ton | mm | CM² | CM³ | mm | mm | mm | mm | mm | mm | mm | mm | kg | |

| BMSL-50 | 5 | 6 | 7.1 | 4.3 | 33 | 39 | 59x42 | 25 | 25 | 21 | 21 | 28.5 | 1 |

| BMSL-100 | 10 | 10 | 14.5 | 16 | 42 | 55 | 83x56 | 38 | 34 | 28 | 28 | 36.5 | 1.4 |

| BMSL-200 | 20 | 11 | 28.6 | 31 | 51 | 63 | 101x76 | 51 | 39.6 | 40 | 40 | 49 | 3.1 |

| BMSL-300 | 30 | 13 | 42 | 55 | 58.5 | 71 | 117x95 | 66 | 44.5 | 48 | 48 | 52 | 4.5 |

| BMSL-500 | 50 | 16 | 62.1 | 99 | 67 | 83 | 140x114 | 70 | 54 | 57 | 57 | 66.5 | 6.8 |

| BMSL-750 | 75 | 16.00 | 102.70 | 164.00 | 79.00 | 95.00 | 165x139 | 83.00 | 66.00 | 69.00 | 69.00 | 76.00 | 11.40 |

| BMSL-1000 | 100 | 16.00 | 126.80 | 203.00 | 86.00 | 102.00 | 178x153 | 92.00 | 74.50 | 76.00 | 76.00 | 76.00 | 14.50 |

| BMSL-1500 | 150 | 16.00 | 198.10 | 317.00 | 100.00 | 116.00 | 215x190 | 115.00 | 82.00 | 95.50 | 95.50 | 117.00 | 26.30 |

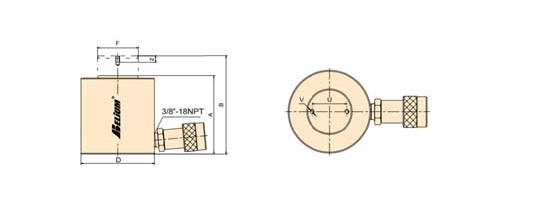

| MODEL |

CYLINDER CAPACITY @ 10,000 PSI (700 BAR) |

STROKE | CYLINDER EFFECTIVE AREA |

OIL CAPACITY | COLLAPSED HEIGHT | EXTENDED HEIGHT | OUTSIDE DIAMETER | PISTON DIAMETER | BASE FIXTURING HOLES | WEIGHT | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| BOLT CIRCLE | THREAD | THREAD DEPTH | ||||||||||

| A | B | D | F | U | V | Z | ||||||

| METRIC TON (US TON) | MM | CM² | CM³ | MM | MM | MM | MM | MM | MM | MM | KG | |

| BMSL-101 | 10 | 38.00 | 14.40 | 55.00 | 88.00 | 126.00 | 126.00 | 38.00 | 26.00 | M4 | 8.00 | 4 |

| BMSL-201 | 20 | 44.00 | 28.60 | 126.00 | 98.00 | 143.00 | 143.00 | 51.00 | 39.50 | M5 | 8.00 | 5 |

| BMSL-302 | 30 | 62.00 | 41.90 | 260.00 | 180.00 | 180.00 | 66.00 | 39.50 | M5 | 8.00 | 7 | |

| BMSL-502 | 50 | 60.00 | 62.10 | 373.00 | 122.00 | 182.00 | 182.00 | 70.00 | 39.50 | M5 | 8.00 | 11 |

| BMSL-1002 | 100 | 57.00 | 126.90 | 723.00 | 141.00 | 198.00 | 198.00 | 92.00 | 55.50 | M8 | 10.00 | 23 |